In this article, we will tell you how Top3dShop scanned an electric car for EVTech using a 3D scanner RangeVision PRO. The aim of the project was to change the design and improve the details of the car. According to the results of the scan, it was necessary to upgrade the car’s body, hood, and fenders, manufacturing them using the method of rotational molding and automatic vacuum forming.

In the short time, it was necessary to refine the body and internals of the car, to simplify the placement of several components and assemblies and then upgrade the design according to the changes.

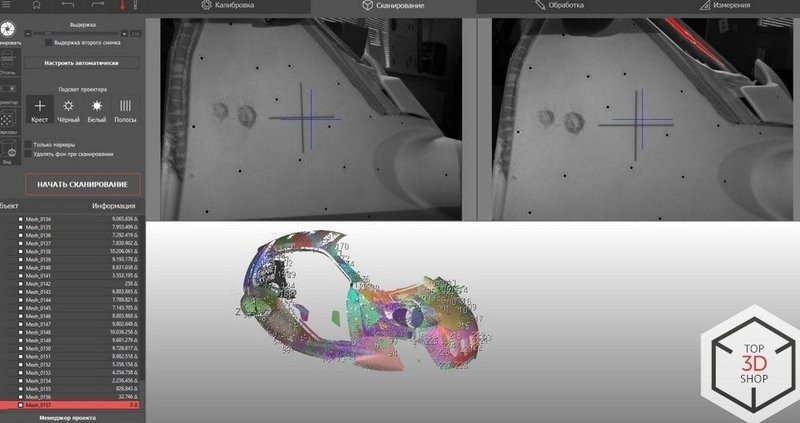

The reflective and glaring surfaces were covered before scanning.The markers were applied in order to create a grid that helps the scanner to calculate the coordinates of the points. The equipment and the calibration board were also installed for quick calibration in case the scanner has been moved.

The markers are placed in a random order, so their position relative to each other is never the same, so there will be no problems during frame alignment and the scanner will be able to accurately detect the shape of the scanned surface.

To combine and save projects consisting of more than 1,500 points, it was used the automatic simplifying function available in the RangeVision ScanCenter software.

Top3DShop was satisfied with the result of the work: “Provided the recommendations for work and setup were met, the RangeVision PRO has proven to be a high-quality professional scanner. We can recommend it to be used for engineering purposes in various fields, including R&D of body parts of cars, motorcycles, small boats and motorboats, for modding and repair”.