Reverse Engineering – Software

RangeVision ScanCenter software is designed to perform 3D scanning and post-processing of the obtained data. Our software is not divided into editions. We do not cut its functionality. All the updates and features are available regardless of the model of 3D scanner from RangeVision. Our developers use only unique algorithms of digitizing and post-processing of the obtained data when creating our software.

The main advantages of RangeVision ScanCenter are

Main functions

An intuitive interface and a convenient setup wizard makes it easy to calibrate 3D scanner and use software even without experience with 3D scanners.

ScanCenter NG supports operation in three scanning modes: on the automatic turntable, with markers and in free scanning mode.

The program supports scanning with color and has the function of automatic adjustment of the white balance, which is important if the received data is used for 3D color printing or in computer graphics, animation and presentations.

User can choose between scanning speed and detail by changing the resolution of the cameras.

The ability to combine scans in automatic and manual modes by geometry or markers.

There is a function to clear scan data in automatic and manual modes, including automatic removal of the background.

Function for filling holes when building a final model.

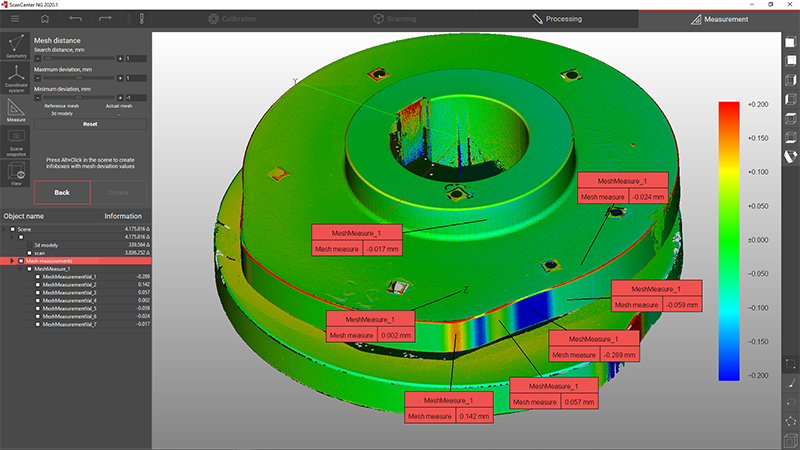

Mesh distance control allows to visualize the deviations in the form of a colour map and take measurements at each individual point of the inspected 3D mesh.

The function of final alignment by selection allows to locally align several meshes in a selected area and is useful for alignment of the reference and inspected meshes by basic geometry.

The function of importing CAD files to STEP format with automatic mesh triangulation provides ScanCenter NG communication with 3D modeling systems.

The functionality for detecting geometric primitives provides measurements of linear dimensions and diameters right in the software.

The software provides support for photogrammetry, it is possible to import reference meshes. This method allows you to minimize the accumulated error during 3D scanning, as well as digitize areas of the object that are distant from each other without capturing all surfaces between them.

The vibration tracking function provides real-time monitoring of the scanner displacement relative to the scanning object or calibration plate during scanning and calibration. That ensures the detection and exclusion of low-quality scans and more accurate calibration.

Automatic exposure calculation helps the user to select the optimal scanning parameters in difficult lighting conditions.

Convenient export of snap view allows to save both the results of the measurements and the results of building regular and textured models in the most popular 2D graphics formats (JPEG, PNG, BMP, PDF) with the ability to select the image resolution.

Mesh smoothing is designed to reduce surface roughness; user can smooth the mesh completely or locally in a selected area.

Option to scan with double exposure will be useful when working with contrasting objects.

Automatic simplification of visualization when there is not enough RAM on a PC is implemented.

Scaling of the final model is possible.

Export data in formats: STL, OBJ, PLY, PTX, ASCII.

| Operation system | Windows 7/8.1/10 64bit |

| CPU | Intel Core i3/i5 1.8 GHz (Broadwell-based) or better |

| Graphics hardware | Video card with dual monitor support |

| RAM | At least 8 GB |

| Other | 3 USB ports |