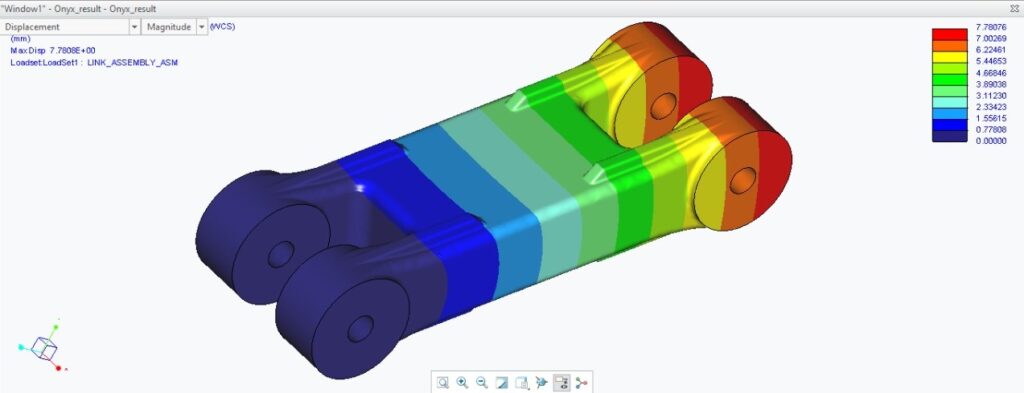

Fork-end assembly used to lift robot arm designed and 3D printed by MRO Engineering using Markforged Mark Two Composite 3D printer/Source: MRO Engineering and Supplies

About MRO Engineering

Nagpur-based MRO Engineering and Supplies Pvt. Ltd. is an industrial engineering firm that offers maintenance and repair products and services since 2017. They offer contract manufacturing, R&D, project planning, and consulting to many international industries.

The Challenge

MRO began as a supplier of parts for maintenance, repairs, and operations. They would scout the market for whatever part was requested and essentially resell it to their customer.

When a part was to be built, they acquired the customer’s design for the specific part and manufactured the parts using traditional manufacturing processes such as casting, machining, etc. However, traditional manufacturing resulted in longer manufacturing and delivery lead times, lesser orders and opportunity loss. Even when it was simply reselling, they frequently faced difficulty obtaining the part because it was dependent on availability with the vendors.

MRO sought to develop an integrated approach in which they had significantly greater control over the deliverables and the solution was under one roof.

The Solution

Directors Abizar and Murtaza, both engineers, were well aware of the possibilities that 3D printing provided. They discovered by 2021 that relying on traditional manufacturing resulted in numerous missed opportunities. Abizar saw an opportunity that could be capitalised on by producing aluminium-strength 3D printed parts with a 3D printer.

“We needed the 3D printed parts to be used for end-use applications with good build speed, high precision, and good surface finish while also being cost effective to help us achieve our break-even point quickly, which is precisely what Markforged provided.” recalls Abizar.

“With 3D printing, we now have complete control over everything. When we require a part, we can deliver it quickly.”

– Murtaza Cochinwala, Technical Director, MRO Engineering and Supplies Pvt. Ltd.

MRO’s first major project was to create a fork-end and brackets assembly used to lift robot arms with a tilt range of 45 to 60 degrees. The team quickly designed the part after analysing its function & performance and 3D printed it with Markforged’s Onyx material due to its ability to provide the required strength and durability.

As a result, the part was created and delivered to the Robotics industry customer on time. The component’s innovative design marked the start of a new era in MRO. An era in which they were finally in charge of the entire process.

Murtaza added, “We have significantly reduced the lead times to just 7 days (including design time) and this has allowed us to take more orders. Our order quantity has increased by 75-85% since we started using Markforged’s Mark Two 3D printer, and definitely we will receive even more orders and grow further.”