Meltio Engine Robot Integration – Meltio’s metal additive manufacturing technology offers two metal AM solutions, the turn key M450 metal 3D Printer and the scalable Meltio Engine for easy integration with industrial motion hardware such as CNC machines and robot cells.

Industrial Metal 3D Printer

Turn a robot arm into a metal 3D printing system with no inherent size constraints. The Meltio Engine Robot Integration is the perfect platform for large and complex 3D printing, repair, cladding and feature addition.

The most affordable large scale metal 3D printing solution, the Meltio Engine integrates with any robot arm manufacturer and interface in the market.

High Complexity

Create highly complex parts with infinite degrees of freedom.

Retrofitting

Provide new capability to any robot arm by turning it into a metal 3D printing system.

Part Repair

Cost-effective component repair, part augmentation and feature addition.

Large Size

No inherent constraints when the working envelope is only limited by the size of the motion system.

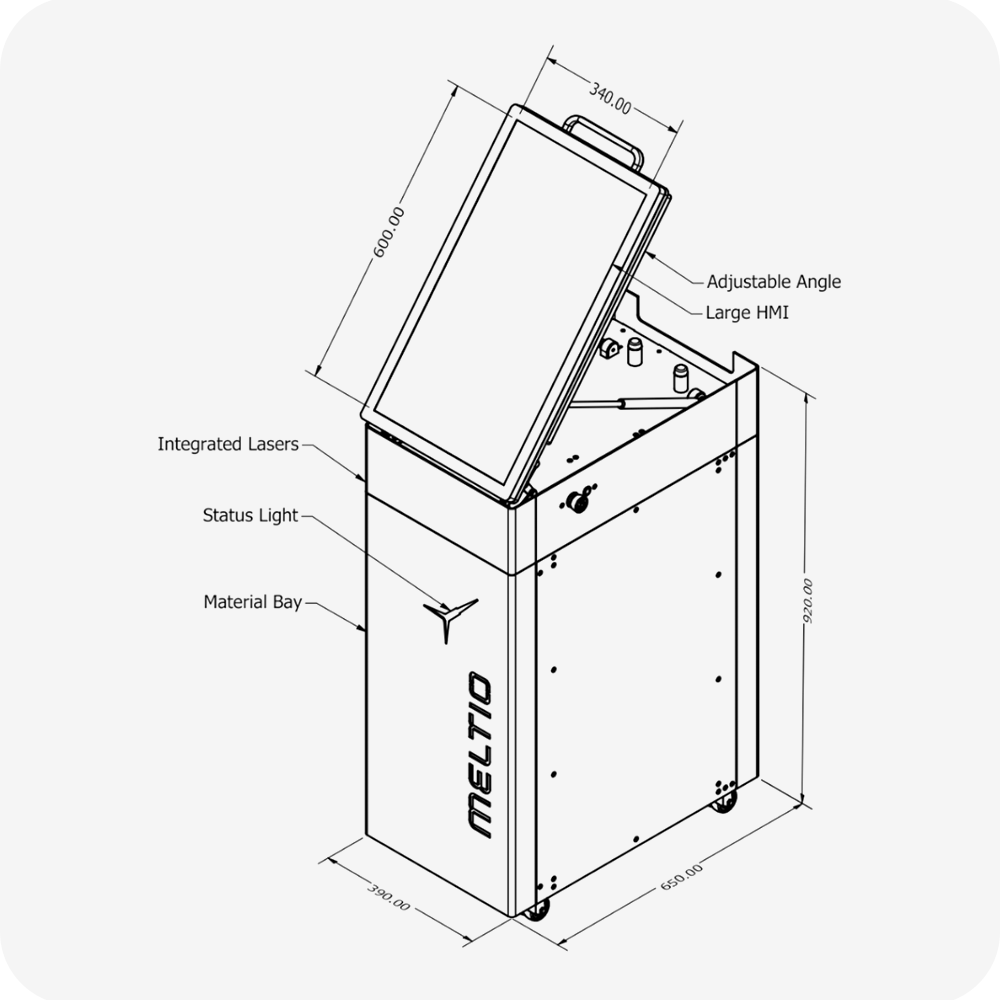

Meltio Engine Specifications

Dimensions (W*D*H):

390*650*1000mm

Print Envelope (X*Y*Z):

inherent to motion system

Weight:

142kg

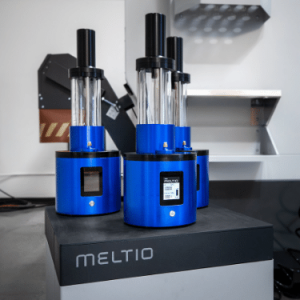

Laser Power:

1200W

Laser Type:

multiple 200W Direct Diode Lasers

Laser Wavelength:

976nm

Process Control:

closed-loop, laser and wire modulation

Power Input:

208/230V Single Phase or 400V Three Phase

Power Consumption:

2-5kW peak depending on selected options

Wire Feeds:

from one K300 spool up to two external wire drums

Wire Feedstock:

0.8-1.2mm wire diamater

Powder Feeds:

external plug and play powder feeders

Powder Feedstock:

45 to 90um particle size

Cooling:

water-cooled chiller included

Custom mounting hardware for the deposition head and upper enclosure for electronics and related sensors.

Custom mounting hardware for the deposition head and upper enclosure for electronics and related sensors.

Dimensions (W*D*H):

202*297*784mm

Weight:

15.5kg

Minimum requirements for a successful integration of the Meltio Engine with a robot arm are:

Minimum requirements for a successful integration of the Meltio Engine with a robot arm are:

- Payload of at least 20kg (60kg recommended)

- More than 3 digital input ports available

- More than 3 digital output ports available

- Enclosed room with safety locks

- Laser safe windows and/or camera

*A laser safety enclosure and safety interlocks for the robot cell are not included. These additional hardware items are to be sourced by the integrator or end user customer because they will depend on the final application and installation facilities.

Upgrades and Accessories

Upgrades and Accessories

Hot Wire

Programmable power supply that preheats the material to increase the deposition rate.

Dual Wire

This option allows to 3D print two wire materials sequentially with very quick wire switches.

Powder Feeder

Necessary to 3D print from powder feedstock, unlocks on the fly metal alloying.

External Wire Drum

Draw from an external wire source. Drums from 100kg may be used for convenience.