Mark Two – Continuous Fiber 3D Printer, built to revolutionize your manufacturing operation

Industrial Desktop 3D printer

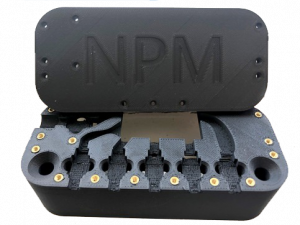

Dunlop Systems is using their Markforged composite printer to help bring an electric car to the market for a large automotive company. The electric car is currently out on the road with 3D printed Onyx prototype parts, and the custom 3D printed tooling done is shown here as a Markforged case study

The electronics housing for the Neurophotometrics system takes just under 11 hours to print.

Carbon Fiber Strength

Print Continuous Carbon Fiber reinforced parts on your desktop – stiff, strong, extremely durable, and capable of replacing machined aluminum.

Built to Last

A unibody aluminum chassis and precision-machined components deliver lights-out reliability over thousands of print hours.

Precise and Beautiful Parts

Print precise parts with best-in-class surface finish thanks to Onyx, Markforged’s extremely versatile micro carbon fiber filled nylon material.

Precision-built so you can 3D print precise parts.

Printing Process

Continuous Fiber Reinforcement (CFR)

Z Layer Resolution

100 μm – 200 μm

Printing Media

Composite Base Filaments, Continuous Fibers

Internal Part Geometry

Closed Cell Infill with Continuous Fiber Reinforcement

Print Bed

Precision Ground Composite

About Mark TWO Industrial Desktop 3D Printer

Physical Dimensions

| Width | 584 mm |

|---|---|

| Depth | 330 mm |

| Height | 355 mm |

| Weight | 16 kg / 35 lbs |

Build Volume

| Width | 320 mm |

|---|---|

| Depth | 132 mm |

| Height | 154 mm |