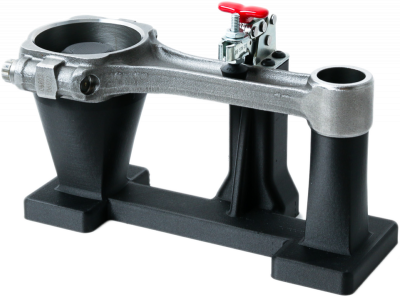

Inspection fixtures

Monotech Systems recently introduced its Additive Manufacturing inspection fixtures. Inspection is a routine component of the manufacturing process; as parts come off of the production line, some are examined to ensure accurate dimensions. Two examples include coordinate-measuring machine (CMM) fixtures and check gauges. A CMM is a precision tool that probes multiple points on a part to determine if the geometry is within specification. Check gauges are another form of inspection fixture used to quickly and accurately determine if parts are satisfying basic tolerances. With 3-axis mills, complexity is already restricted by machine-specific limitations, such as the inability to perform undercuts. After the part is designed for traditional manufacturing, it must be prepared in CAM to machine the fixture. Alternatively, utilising composite 3D Printing to manufacture fixtures allows the user to produce stiff, precise workholding while cutting out the CAM process. Eiger, takes care of all of the preparation; so, all user has to do is design then start the print. Higher geometric complexity can be printed with no extra effort, allowing for intricate form-fitting fixtures to be produced at a lower cost.

Check out the coverage on Inspection fixtures in the EM (Efficient Manufacturing) JANUARY 2022 digital edition.

Inspection fixture