3D Printing for Consumer Technology

Additive manufacturing solutions that advance consumer technology performance and accelerate time-to-market from design to pre-production.

10x

500K+

130+

Accelerate Innovation to Bring the Consumer Technology Products of the Future to Market Now

Consumer technology has become prolific in our everyday lives, spurring a revolution from devices for smart homes to connected wearables. To differentiate your company in this extremely competitive industry, you need to bring groundbreaking products to market faster and constantly create unique customer experiences that deliver value. This level of consumer demand drives the need for design flexibility, prototype performance, rapid iteration, supply chain continuity, sustainable solutions, and operational productivity from prototyping to bridge production and mass customization.

3D Systems’ consultative approach and 3D printing solutions can give you a competitive advantage to meet these challenges. With a dedicated team of experts and decades of industry experience, we collaborate with you on application development and leverage the largest suite of additive manufacturing solutions in the industry to meet your specific needs.

3D Printing Applications for Consumer Technology

3D printing solutions can address prototyping and low-volume production needs for a vast array of new and emerging consumer technologies. This can range from virtual and augmented reality, to enter the immersive online environment of the metaverse, to smart homes, IoT, AI, 5G, connected wearables, computers, and other consumer electronics.

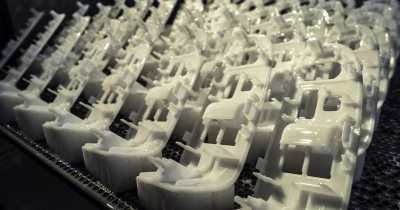

Housings and Covers

Consumer technology products can present daunting engineering challenges to quickly deliver excellent quality, fit, and finish. 3D printing eliminates tooling costs and lead-times for housings and covers, whether for prototypes or bridge production, with materials that deliver advanced mechanical properties and long-term environmental stability.

Seals and Gaskets

Creating seal and gasket prototypes for testing and end-use validation is critical to ensure perfect fit of your consumer products, and can be time consuming and expensive to produce with conventional methods. For rapid design iteration and prototyping of true silicone components, 3D printing eggshell molds is a fast and cost-effective alternative to injection molding. Similarly, direct 3D printing of biocompatible, chemical-resistant elastomers can open additional possibilities for concept and functional prototypes.

Wearable Components

To develop comfortable wearable consumer technology with the perfect fit, many design options need to be tested and validated. Our 3D printing solutions enable rapid iteration of high performance prototypes, delivering rapid order fulfillment and faster time-to-market. With a portfolio of materials offering advanced mechanical, thermal, elastomeric, chemical resistance, and biocompatible properties, there is a suitable material for a vast array of wearable components applications.

3D Printing Solutions that Accelerate Innovation

Complete Solutions Portfolio

Our hardware, software, materials, post-processing, and manufacturing operating system (MOS) solutions offer unprecedented speed, quality, design flexibility, economics, and product reliability. 3D Systems offers the largest suite of additive manufacturing solutions for plastic and metal 3D printing, with 7 technologies, over 130 materials, and more than 1,000 patents during the past decade.

Production-Grade Materials

Our 3D printing materials address the widest variety of applications and performance characteristics in additive manufacturing to offer a range of features that are critical to prototyping and production for consumer technology products. Our diverse portfolio includes photopolymers with long-term stability and mechanical properties similar to production thermoplastics, heat-resistant materials, biocompatible materials for extended contact with skin and chemical resistance, and elastomers for wearables.

Partner with 3D Systems to Enhance Design to Production Workflows

Responsiveness

With 3D Systems’ solutions capable of 3D printing prototypes in less than 24 hours, OEMs can optimize their workflow to reduce the time between design iterations, enabling rapid order fulfillment and faster time-to-market. In-house production guarantees part delivery for a streamlined supply chain while our Customer Innovation Centers offer flexibility to increase capacity.

Design Flexibility

Optimally design, rapidly iterate, and manufacture highly complex parts. Components that were previously unthinkable to produce can easily be made a reality by leveraging 3D printing. Additive manufacturing delivers advanced parts with immediate turnaround and rapid product iteration capabilities, eliminating the time and cost of tooling.

End-Use Performance with Production-Grade Materials

Accuracy, precision, and mechanical properties are critical factors for product validation and end-use components. Achieve production performance with advanced 3D printing solutions and materials that deliver parts with final product look, feel, mechanical characteristics, quality, and performance.

Operational Productivity

Our end-to-end additive manufacturing solutions are designed to deliver industry-leading quality, reliability, and productivity to keep your operation running efficiently for high-volume production of prototypes, bridge manufacturing, and mass customization. Maximized uptime, reduced labor enabled by downstream compatibility with automation, and minimized waste contribute to a lower cost per part and high manufacturing yield.

Mass Customization

Designing and building customized components is part of creating next-generation consumer technology products. Tailoring these to the consumer can be costly with conventional methods. We facilitate mass-customization by giving engineers precise control over each component, to create a unique customer experience, with the capability to scale.

Sustainability

We focus on developing solutions to enable our customers to address evolving sustainability challenges, considering strategies such as advanced materials, production on-demand, and improved efficiencies through additive manufacturing capabilities.