Accelerate sustainability initiatives, differentiate through customization, establish new benchmarks for asset availability, and be more adaptable to new regulations with our additive manufacturing solutions and services

3x

90%

25%

Exceed Customer Expectations and Deliver Products Faster by Staying Ahead of Regulations

In order to grow and differentiate from the competition, commercial and public transportation companies are pushing for lower costs, enhanced performance, and flexible product platforms that can quickly adapt to new technologies and customer requirements.

Our extensive portfolio of additive manufacturing technologies, materials, and software can give you the competitive advantage you need to meet these challenges. Through our understanding of the application needs for the railway, truck, and bus industries, we will empower your innovation.

Additive Manufacturing Applications in the Truck, Bus & Rail Industry

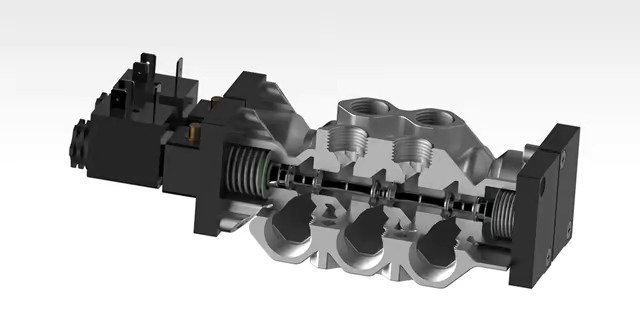

Brake Systems & Pneumatic Controls

Optimize compressed air system performance, quality, and reliability by reducing component weight and part count and integrating multiple functions into a single part. 3D Systems offers a breadth of additive manufacturing technologies and materials that can help you enhance your product development and manufacturing process with quick iteration and production of innovative brake systems and pneumatic controls.

Power Electronics Enhancement

Unlock new efficiency in energy transmission and increase the durability of insulated-gate bipolar transistors (IGTBs) and inverters with more effective heat sink systems enabled by conformal cooling channels. As a bonus, this unique AM capability can also solve a wide range of packaging challenges. 3D Systems’ applications engineers have extensive experience across a wide range of industries to help you design innovative heat exchangers and heat sinks with the best material and process for your transportation applications.

Interior & Passenger Comfort

Differentiate your vehicle interiors to optimize comfort, functionality and riding experience for both passengers and operators with faster innovation, iteration, and validation on production parts without tooling investments. With our innovative polymer materials and advanced software applications, you can 3D print prototypes with realistic textures and surfaces as well as final production parts that meet the latest transportation industry regulations.

Molds & Patterns for Sand Metal Casting

Accelerate production delivery, optimize parts, and reduce manufacturing costs by creating reusable patterns and cores for the traditional sand-casting production process. Our advanced software applications and large selection of composite SLA materials will help you to quickly and easily optimize designs and produce patterns and cores with excellent wear resistance and superior surface finish for the final part.