PLASTIC ADDITIVE MANUFACTURING SOFTWARE

Why 3D Sprint?

- Use a single software application from CAD to print.

- Increase efficiency with optimized data management.

- Streamline time to print and finished parts with a single, easy-to-use interface.

- Improve productivity and reduce printer downtime with management and monitoring tools.

- Print better parts.

What Can You Do with 3D Sprint?

IMPORT

Directly import native CAD files from industry-leading CAD systems, which greatly reduces the need for file repair and fixing, shortens the file preparation time, and facilitates the design-to-print process.

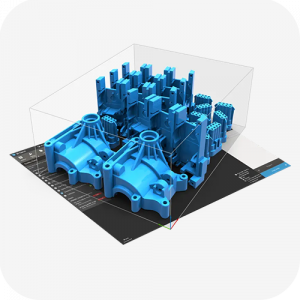

SUPPORT

Achieve better surface quality for printed parts that are easier to remove using less material and post processing with automatic, intelligent, finely-tuned support generation and optimized preset profiles accompanied by a full range of structure and anchor point extraction parameters.

REPAIR

Automatically analyze part geometry; correct errors for translation issues in your CAD or STL design files and bad polygon geometry in 3D scans; and select, edit, and delete polygons and intelligently fill holes and gaps in your polygon data with manual polygon editing tools.

PRINT

Achieve accurate and powerful slicing and accurate build time and material estimates. Submit print jobs directly from your print workspace or load 3D Sprint build files created on another system directly to the printer. Manage your directly-connected printer or get visibility for all networked or shared printers to control job priorities with queue management tools.

PLACE

Save custom placement styles and optimize the printer volume for maximum efficiency and productivity with comprehensive auto placement including requirement-driven orientation, dense 3D nesting, and automatic pre-printing quality checking.